|

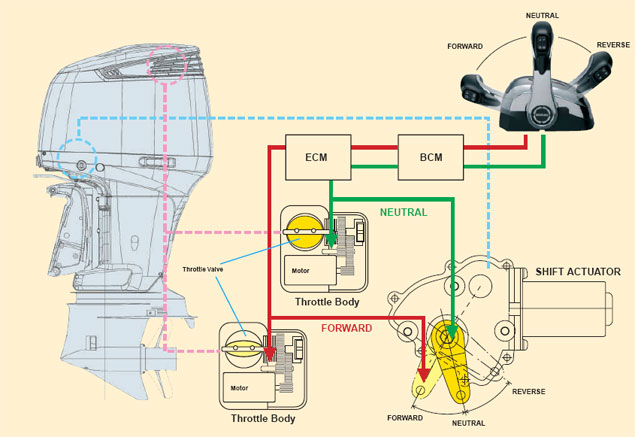

Suzuki Introduces the Industry's In 2003, Suzuki shook the industry with the introduction of the first ever 250 horsepower 4-stroke outboard, the DF250. Its leading edge technology received high acclaim and garnered Suzuki its fourth National Marine Manufacturers Association Innovation Award. Three years later, Suzuki has set the standard again with the introduction of the first ever 300 horsepower 4-stroke outboard, the new DF300. As the most powerful outboard Suzuki has ever manufactured, it offers owners of large boats the performance and cruising comfort they demand, and at long last, provides this class of boaters with all the advantages that 4-stroke outboards have to offer, like quiet operation and superior fuel economy. The DF300 is Suzuki's first outboard to feature the Suzuki Precision Control System, an advanced system which provides quicker throttle response and smoother, decisive shifting. The DF300 also features Suzuki's proven technologies, like Variable Valve Timing (VVT), an offset drive shaft, a two-stage cam drive system, Mutli Point Sequential Electronic Fuel Injection, and more. All technologies that have brought Suzuki awards and acclaim, and that are found throughout Suzuki's 4-stroke lineup. In addition to its technological advantages, the DF300 is designed with the environment in mind, providing boaters with low emissions and excellent fuel economy-noteworthy benefits of Suzuki's superior 4-stroke outboard technology. The DF300 meets both the Environmental Protection Agency's (EPA) 2006 federal exhaust emission standards and the California Air Resource Board (CARB) 2008 3-Star Ultra-Low Emission standards. Suzuki's DF300 sets new standards for 4-stroke outboard power, performance and fuel efficiency while meeting strict emission standards. |

|

|

|

Main Features of the DF300

|

|

||||||||||||

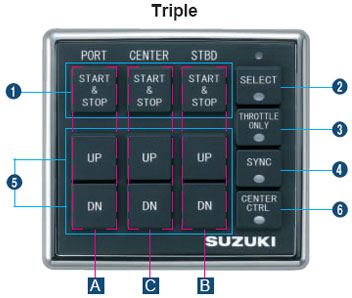

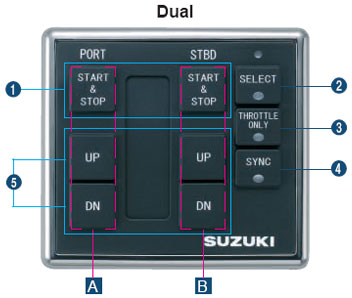

Control Panel

Suzuki's Remote Control System puts precision operation right at your fingertips.

|

|

|

| Start Stop Switch. Switches the engine ON/OFF. | |

| Station Select Switch. Switches control between driving stations on boats equipped with more than one driving station. | |

| Throttle Only Switch. Keeps the drive in neutral for throttle operation. | |

| Engine Synchronize Switch. Synchronizes engine RPM on boats with two or more outboards. | |

| Tilt Up & Down Switch. Tilt control for each engine. | |

| Center Engine Control Switch. The center engine is controlled with the portside remote controller (auto on). With the control in the neutral position, this switch locks the center engine in neutral letting you operate with the remaining two outboards. | |

| Port-Side Engine Controls | |

| Starboard-Side Engine Controls | |

| Center Engine Controls |

Serial Indicators and Monitoring System

Tachometers and speedometers feature Suzuki's innovative serial indicator and monitoring system, which puts a wealth of vital information right at your fingertips.

|

Tachometer

|

|

|

|

Tachometer

|

|

|

|

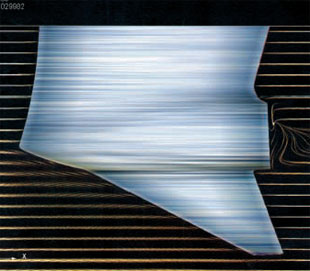

Long Track Intake Manifold Another performance enhancing feature on the DF300 is a long track intake manifold. Using long intake pipes with an inline layout tuned to smooth airflow into the engine the system provides the DF300 with enhanced power.  Streamlined Gear Case The gear case on the DF300 has a new hydrodynamic design that reduces drag created as the lower unit moves through the water. This contributes to faster acceleration and increased speed.  |

|||||||||

|

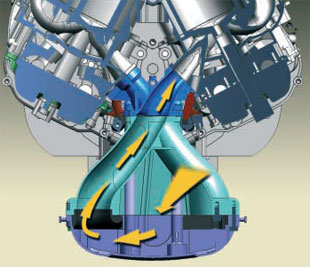

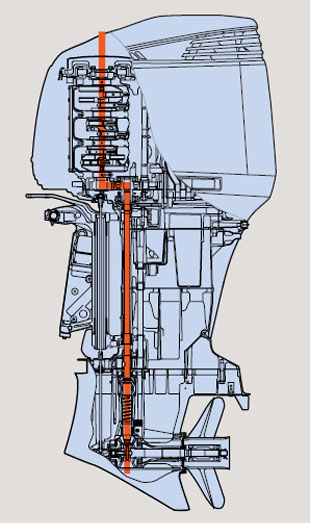

Large Air Intake with Water Separator The DF300 is designed with a large air induction port to maximize airflow into the engine in order to obtain maximum power output. The increased airflow produces more low- to mid-range torque and provides a wide powerband that is necessary in an outboard engine. Suzuki also designed the system with a water separator, which aids in keeping water out of the electronic throttle body and a heat shield to keep intake air from being heated by the engine.  Offset Driveshaft Suzuki outboards are among the most compact outboards in their respective classes. That's due in part to the utilization of Suzuki's proven offset driveshaft system. This design places the crankshaft in front of the driveshaft through the use of intermediate reduction gearing. In addition to providing an improvement in power performance and adding to the compactness of the outboard, this system moves the outboard's center of gravity forward, resulting in contribution to weight distribution, balance, directional stability, and less vibration.  Direct Ignition System Supplying spark to the big V6 engine is an advanced ignition system that utilizes integral type spark plug caps with built-in ignition coils. The system is controlled by the outboard's powerful 32-bit computer and provides each cylinder with optimum spark timing. In addition to reducing the number of parts and simplifying the wiring system, this arrangement greatly reduces electronic engine "noise" that can interfere with VHF radios, fish finders, and other marine electronics.  Plug Top Ignition Coil |

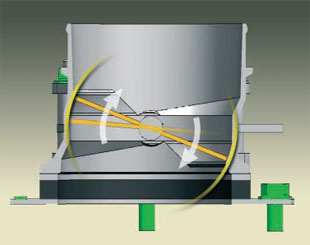

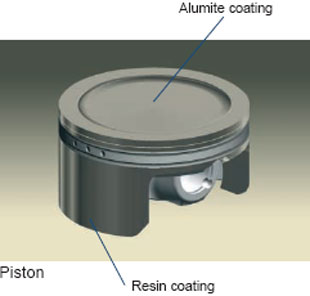

Spherical Bore Throttle Body A spherical bore throttle body smoothes the characteristically turbulently airflow into the engine that occurs as the throttle begins to open. Providing a smoother airflow during acceleration results in improved throttle control and stable engine operation at low rpm.  Fuel Cooler The cooler the fuel the denser it is, and the denser it is the better performance it delivers. Incorporating a fuel cooler in the DF300's fuel delivery system cools the fuel before it enters the engine. Providing the engine with an optimum fuel supply results in better combustion and performance. Forged Pistons The upper portion of pistons used in the big V6 engine is treated with an alumite coating that increases heat resistance. A resin coating applied to the piston skirt improves resistance to wear and reduces friction.  Fuel Filter with Water Separator The fuel system incorporates a large, easy to maintain fuel filter that removes contaminants from the fuel before they can reach the engine. A water separator built into the fuel filter offers a heightened level of protection by keeping water out of the engine.  Water-Cooled Voltage Regulator The outboard's electric system includes a water-cooled voltage regulator that dissipates heat in the regulator to enhance engine durability. 32-Bit ECM and Suzuki's Multi Point Sequential Electronic Fuel Injection Suzuki pioneered the use of multi point sequential electronic fuel injection in four-stroke outboards with the introduction of the DF60 and DF70-the first four-stroke outboards designed with multi point sequential electronic fuel injection. At the heart of the DF300's multi point sequential fuel injection system is the ECM (Engine Control Module), which constantly monitors crucial data, in real time, from a series of sensors placed in critical areas on the engine. This comprehensive network of sensors includes the Manifold Absolute Pressure Sensor, Crankshaft Position Sensor, Intake Air Temperature Sensor, Cylinder Wall Temperature Sensor, Camshaft Position Sensor, and Exhaust Jacket Temperature Sensor. Using a very powerful 32-bit computer, the ECM processes data from all of these sensors and instantly calculates the optimum amount of fuel to be injected at high pressure into each of the V6's cylinders by the multi point sequential fuel injection system. Benefits of this system include reduced exhaust emissions, which allow the DF300 to comply with CARB 3-Star emission requirements, lower fuel consumption, smoother starts, crisper acceleration, smoother performance, and maximum efficiency. |

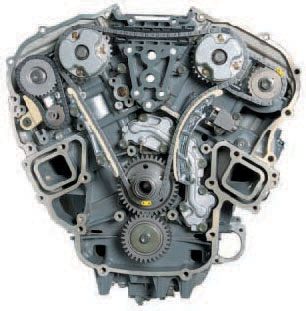

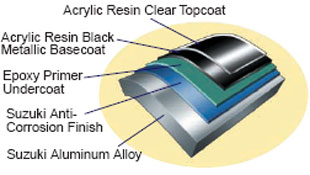

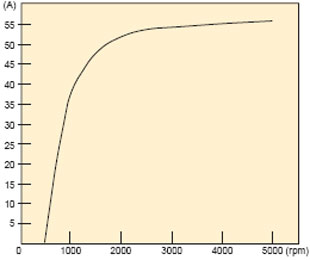

Two-Stage Cam Drive System The DF300 utilizes a two-stage cam drive system that incorporates both gears and a chain. First stage gears transfer power between the crankshaft and the drive shaft from which a second stage utilizes a chain to deliver power from the driveshaft to the camshaft. This system allows for the use of smaller cam sprockets, which in turn allow for a reduction in valve angles also reducing the size of the cylinder head. An automatic hydraulic tensioner incorporated into the timing chain system keeps the chain properly tensioned and provides years of maintenance-free operation.  Suzuki's Anti Corrosion Finish The outside of the DF300 is covered with Suzuki's anticorrosion finish that is specially formulated to increase the durability of the engine and help protect parts of the aluminum exterior that are constantly exposed to saltwater. This advanced finish offers maximum bonding of the finish to the outboard's aluminum surface, creating an effective treatment against corrosion.  Dual Engine Flush Ports The build up of sand and salt in the engine's cooling system can lead to engine damage. To aid in reducing such buildup, the DF300 is designed with two freshwater flush ports that make flushing of the cooling system as convenient and easy as possible. With one port located on the rear panel and the second on the front panel, access is easy and flushing out the system is possible whether the boat is in or out of the water.  Fuse Box Fuses protecting the DF300's electric system are assembled into a single fuse box located on the side of the outboard motor, which provides convenient access while offering a clean exterior. High Output Alternator The Suzuki DF300 generates electricity from a high output alternator that delivers 54A (12V) of electrical power. Suzuki's design allows the alternator to produce a majority of its output at low rpm, so even when operating at 1000rpm it can produce approximately 38A of power. In most situations, this is enough power to keep an assortment of electronics up and running.  |

|||||||||||||

|

Regulator with Dual Circuit Charging System The motor DF300 incorporates a dual circuit charging system that can be adapted* to accommodate the dual-battery configurations often used on large boats. When used in this configuration the system is designed to charge both the main and auxiliary batteries simultaneously but on independent circuits. With this you can drain down the accessory battery powering your electronics and still have a fully charged main battery for starting the motor. * Utilization of this system requires the purchase of an optional wiring harness.  |

|

|

|

|

|

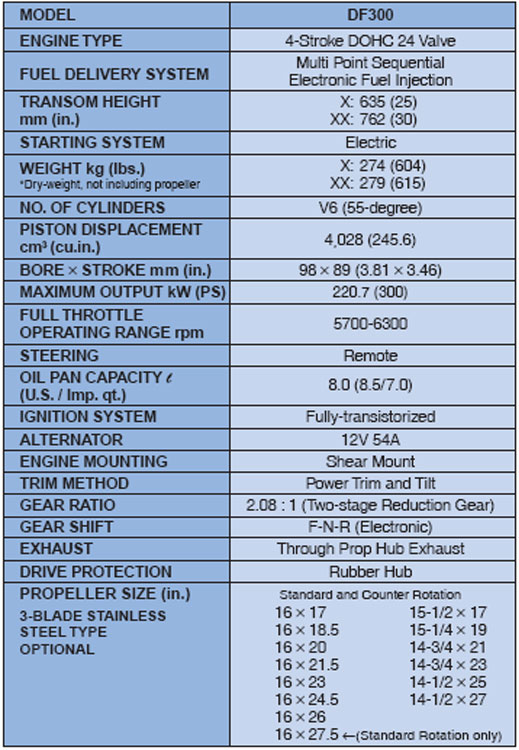

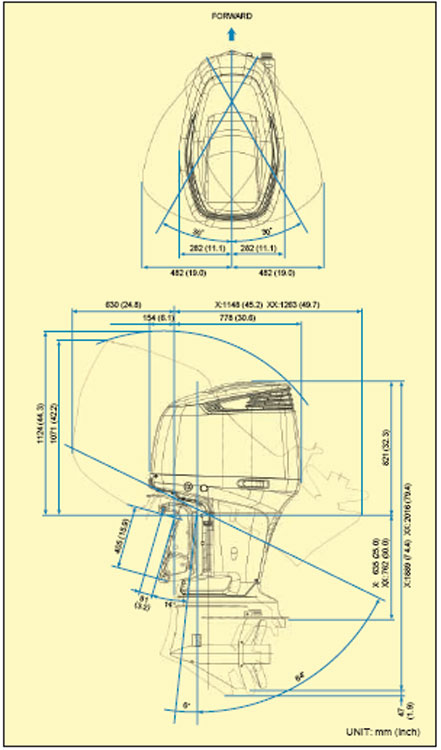

DF300 SPECIFICATIONS  |

DIMENSIONS  |